ACTIVE STORM TRACKER Hurricane and Tropical Storm Information Learn more

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Seamanship

How To Splice Double Braid Line

Advertisement

Mooring warps, halyards, sheets, and plenty of other lines aboard all use double braid. Avoid weak knots by learning how to add an eye splice yourself.

Knots in lines are fine for occasional use, but a splice is better for more permanent use. A splice looks more seaman-like and doesn't affect the strength of the line nearly as much as a knot. Many lines these days are what are known as double braid — essentially an inner core with a cover on the outside. The core and cover share the load equally. Here's how to put an eye splice in double-braid line.

Technical Support

Degree Of Difficulty: Moderate to high

- Double braid splicing fids

- Masking tape

- Permanent marker

- Double-braid line

Time: About 30 mins, but you will get faster with practice.

Cost: Nothing, if you already have the tools and materials. A set of five good quality fids is around $50.

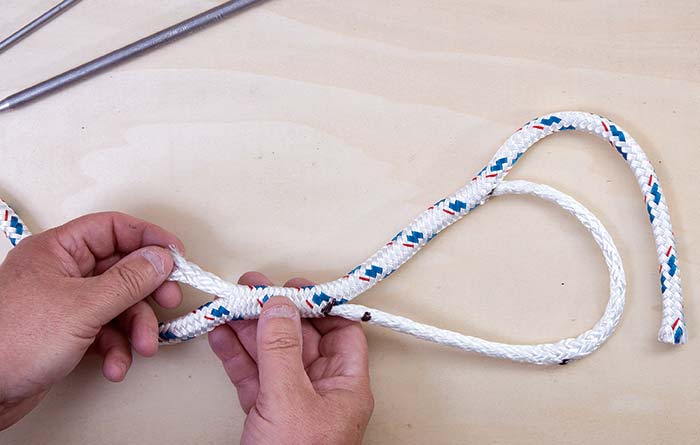

1. Tie a slipknot about 15 feet from the end of the line, and loop it over a winch or cleat to hold it. Make a mark on the line one fid-length from the end .

2. Form a loop or eye to the desired size then place a second mark opposite the first.

3. Using a small fid, separate the strands of the cover at the second mark and pull out the core. (If the end of the line was melted when it was originally cut to length, trim this off with a sharp knife so the core moves freely.) Lay the cord and the cover alongside each other.

4. Mark the core where it comes out of the cover (your third mark), then pull out a couple feet more and place a fourth mark on the core two-thirds of a fid length from the one you just made. That's where you will be inserting the cover into the core.

5. Wedge the end of the core into the hollow end of a fid that matches the diameter of the core , then push the fid into the cover at the first mark. Work the fid down so that it exits the cover 1 to 2 inches past where the core exits.

6. Pull about 6 inches of the core out of the hole. This begins to form your loop. Make sure that both sections of core are not snagged on one another and freely move within the core.

7. Now, wedge the end of the cover into the fid, then feed it into the core at the second mark. Work it down one complete fid length before pulling it out of the core.

8. Starting about 4 inches from the end, use a small fid to pull out about 8–10 random strands from the cover before trimming them off with scissors. This creates a neat splice with a taper.

9. Pull on the end of the exposed core as you massage the junction of the core to cover the joint.

10. To finish off the splice, work the cover back up the line until the exposed core with the cover inside pops back into the line. Pull a little on the core still hanging outside the line, trim with scissors, then tug on the eye to set the end back inside the core.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Contributing Editor, BoatUS Magazine

A marine surveyor and holder of RYA Yachtmaster Ocean certification, BoatUS Magazine contributing editor Mark Corke is one of our DIY gurus, creating easy-to-follow how-to articles and videos. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel — in a kayak! He and his wife have a Grand Banks 32.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

- Skip to main content

- Skip to primary sidebar

- Skip to footer

The Boat Galley

making boat life better

An Easier Way to Splice Double Braid

Published on April 30, 2018 ; last updated on May 1, 2023 by Carolyn Shearlock

It all comes down to the fid. Simple.

We had to replace our spinnaker halyard after Hurricane Irma, and our experience with our first double-braid splice told us we didn’t want to do a second. So we called on our friends at Keys Rigging , in Marathon, Florida.

They said sure, they could do the splice. But why didn’t they teach us an easier way to do one at the same time? Sounded like a good deal to us.

The first thing they said was that standard fids are hard to use (yeah, I’ll agree). They make their own from the center strand of 1×19 rigging wire — you need a piece 18″ or so long. You can get one from the scrap pile at any rigging shop. Fold it in half and tape the ends together. Make sure that the fold is a sharp 180° turn — the closer together the two wires, the easier it will be on the second fid pass.

I’ll be referring to the directions given by Jamestown Distributors here for the initial measuring of the line. If you don’t have a traditonal fid (and why would you since you just made your own?), here’s a handy chart of fid lengths .

Do Step 1 and the first part of Step 2 in the Jamestown instructions, where you pull the core out of the cover. Don’t tape the ends as they suggest. Next, you’re going to taper the cover. From Mark C, go one “fleck” towards the end of the line and pull two strands of the cover out on each side of the line. Do this at every fleck to the end of the line. It’ll look something like this (you can use a needle, paper clip or even the tip of a pen or pencil to pull the strands out. Cut them all off flush with the cover.

Then make Marks 1, 2 and 3 as per the Jamestown instructions.

Put the folded end of your homemade fid into the center of the core at Mark 3 and out at Mark 2.

Thread the tapered end of the cover through the “eye” of the fid.

Pull the fid back out through Mark 3 until Mark A on the cover (the mark just above where the taper starts) is at Mark 2 of the core (letter marks are on the cover, numbers on the core). Where Mark A and Mark 2 meet is called the crossover point. It’s critical that these marks line up, so put a needle or paperclip through the cover and core at this point.

Put the fid in at Mark D and out at Mark C. Be very careful to put the fid between the cover and core and not snag either one of them (snagging either one will make it almost impossible to get the core through). Thread the loose end of the core through the eye and pull the whole fid back to Mark D until the core comes out.

This is really tough. You’re going to say something along the lines of “I thought this was an easier way to splice!” Trust me, it’s considerably harder with a traditional fid. Just keep pulling. Every so often, stop and bend the line back and forth where the tip of the fid is — this will help loosen the cover. Still, once the tip of the fid gets to the point where the cover already has the core in it, it’ll be tough. I bent my fid into an “L” so that I could stand on it while pulling.

Finish with Steps 6 and 7 from the Jamestown directions. I find that it’s best to use a cleat or winch on the boat to hold the end of the line — those are the sturdiest points on most boats.

And check out our other courses and products

Find this helpful? Share and save:

- Facebook 453

- Pinterest 4.7K

Reader Interactions

Anonymous says

April 30, 2018 at 11:57 am

April 30, 2018 at 6:32 pm

Being way too cheap to buy one, I also made my own splicing needle (fid). I used the copper core of some heavy duty Cable TV wire, and epoxied it into a handle made out of the handle-ish-looking shipping spacers from our new washing machine. Works like magic.

April 30, 2018 at 7:09 pm

Another good source for the wire 😀

June 1, 2022 at 2:43 pm

It just moved https://support.jamestowndistributors.com/hc/en-us/articles/360052068854-Splicing-guide-double-braid-eye-splice

Bob Petrasek says

October 12, 2020 at 7:43 pm

Jamestown Distributors does not appear to have a downloadable PDF. of the instructions that you mentioned. They appear to have switched to YouTube videos. They are not clearly explained. Any other sourced that you would recommend?

Carolyn Shearlock says

October 13, 2020 at 1:30 pm

Oh darn! No, I don’t have an alternate source.

David Sliwkoski says

October 28, 2020 at 8:17 pm

I’ve used the Samson splicing kit, which comes with 4 or 5 fids and and a pusher. Number one don’t use the directions that come with the kit. There are a number of videos on YouTube that explain how to make the splice. I use the one from West Marine. Number two: before you start milk the cover back then pull it back into place. This will take the tension out of the cover. Once you do the splice two or three times, you will be able to splice double braid of any size in 10 to 15 minutes or less. I find it so simple that I am more likely to splice a line than tie a not.

November 2, 2020 at 4:28 pm

Thanks for the tips!

Jen Fordyce says

March 20, 2021 at 7:43 pm

Hi Carolyn, thank you so much for these instructions, they are so helpful. I have had a couple of goes at splicing without much luck but will to try as I am such I will get there and this info is great. The last photo shows an image that says wash white line twice before splicing, do you recommend this and is that just in cold water without soap. Does the quality/price of the rope make a difference to how hard it is to splice. Would love any advice on this, thanks

March 21, 2021 at 7:42 am

The WASH refers to your HANDS, not the line. The photo above that shows how dirty my splice got from the dirt on my hands.

I don’t know if lower quality line is any different to splice . . . we only use high quality on our boat.

Michael Scipione says

May 11, 2021 at 4:30 pm

the following instruction on burying the core, Mark C is incorrect as it is already buried in the core past the crossover. Picture shows fid correctly coming out mark A (the crossover). i also found that a cable tie in addition to the needle helps hold the crossover.

May 12, 2021 at 7:12 am

Yes, snagging either the core or the cover makes it infinitely harder! Thanks for the fid info. As stated in the article, I find the wire easier than using a fid but everyone has their own preference!

May 11, 2021 at 4:47 pm

Jamestown Instructions suggest they be printed to a pdf file and saved https://support.jamestowndistributors.com/hc/en-us/articles/360052068854-Splicing-guide-double-braid-eye-splice

and a fid length table http://atlanticbraids.com/wp-content/uploads/2018/07/Fid-Lengths-Measurements.pdf

Col Delane says

August 12, 2021 at 3:10 am

“the center strand of 1 x 19 rigging wire” doesn’t indicate what gauge the 19 strands are, as 1 x 19 rigging comes in wire of multiple thickness.

What thickness do you recommend for the DIY fid?

August 28, 2021 at 3:58 pm

I think ours was from 1/4″ wire.

Helge Tepp says

December 28, 2021 at 4:51 pm

That depends on the size of the rope you want to splice. Look up for D-Splicer. You will find several cailibers there. I use these tools in all sizes and they are sturdy enough to do the job nicely. For a mooring line with an eye of 20″ you will either work the splicing as a series of going in, coming up, diving in at the same spot. Or you go for the xxl Modell, I use it all the time, so far up to a gauge of 20 mm.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Each week you’ll get:

• Tips from Carolyn • New articles & podcasts • Popular articles you may have missed • Totally FREE – one email a week

SUBSCRIBE NOW

- Questions? Click to Email Me

- Visit Our Store

- Cruising Compass Media Advertising & Rates

- Blue Water Sailing

- Multihulls Today

- Subscribe Today

How to Splice Your Double Braid Lines

This article by Andy Cross was originally published in Blue Water Sailing.

Marlinspike seamanship is an often-overlooked aspect of sailing. Most cruising sailors know half-a-dozen knots that are applicable in various situations aboard their boats. But, not many sailors know how to splice an eye in double braid line.

Double braid is popular aboard cruising boats because it is long lasting, strong, has relatively low stretch and is inexpensive when compared to high-tech line. Take a look at your running rigging and you will see that double braid is used almost everywhere, from halyards and control lines to dock lines and sheets, and many of those lines have, or need, an eye splice. If you want to add double braid splicing to your bag of seamanship tricks, here is an easy-to-use tutorial to get the job done.

The essential tools for completing a double braid splice are: a length of new double braid line, a set of Samson Aluminum Tubular Splicing Fids (or similar), an awl or marlinspike, a sharp knife, cutting board, sharp scissors, masking or Marlow tape and a black Sharpie (silver if marking black line). Note: Do not splice used line; even if it has been wet and dry once, it will be very hard to work with.

When you set up to make the splice, tie a knot about six feet back from the bitter end of the line. It is a good idea to anchor the knot to something sturdy such as a cockpit cleat or sheet winch. A solid anchoring spot for the line will make the last steps of the splice easier. Lay out your line on a flat surface and choose one fid that is the same diameter as the line you will be splicing and one that is the next size smaller. Now you’re ready to splice.

Step One: Marking the Cover (fig: 1,2) Measuring and marking the cover and core is absolutely essential to getting your splice to work correctly. Using a fid that is the same diameter as the line, measure one fid length from the end of the line and make your first mark (Mark A). From Mark A, measure your desired eye size and make Mark B. Note: If you are attaching a shackle inside the eye, make the eye slightly larger than you think you’ll need. In most cases, the splice shouldn’t be tight against the hardware. From Mark B, measure one fid length down the line and make Mark C.

Step Two: Extract the Core (FIG: 3) At Mark B, use your awl or marlinspike to retrieve the core from inside the cover. It helps to bend the line sharply to get started and be careful not to snag any strands of the cover as you remove the core.

Step Three: Marking the Core (FIG: 4,5,6) Once the core has been extracted, push the cover towards the knot and then milk the cover back towards the bitter end. This helps to separate the cover and core, which will make the remaining steps easier. Where the core exits the cover make Mark I.

Now push the cover back towards your knot to expose a few feet of the core. From Mark I, measure half-a-fid length and make Mark II. From Mark II, measure one fid length and a half and make Mark III.

Inserting the Core into the Cover (FIG: 7,8) Now you are going to start the actual splice, which will seem a lot like a Chinese finger trap. Tape the end of the core, cut it at a 45-degree angle and tape it to a fid that is one size smaller than the diameter of the line. Try not to use too much tape as it will make the core harder to pass through the cover.

Insert the fid at Mark A and milk it down the line until the tip of the fid reaches Mark C. Remove the fid and that section of the core at Mark C. If you are installing hardware, pass the fid and core through the hardware before inserting the fid at Mark A. Note: Because the core is doubled up inside the cover between A and C, this part of the splice can be difficult. Take it slowly to ensure the fid does not detach from the core.

Step Five: Inserting the Cover Inside the Core (FIG: 9,10) Tape the end of the cover and cut it off at a 45-degree angle, then tape the end to the fid that was used for measuring and marking.

Insert the fid into the core at Mark II and pull it out at Mark III. Now pull the cover tight against the core and visa versa. This is called a crossover and should be snug.

Step Six: TapeR and Bury the Cover and Core (FIG:11,12,13,14) Pull the cover out of the core as much as possible, remove the tape and fid and splay out the cover about a half to one full fid length. Then use scissors or a knife to taper the splayed out strands. Once the cover has been tapered, milk the core over the tapered ends.

Now you are going to basically do the same thing with the cover coming out at Mark C. Pull the core through until the tapered ends of the cover inside the core just meet the crossover. Next, grab the core where it comes out at Mark C, pull the core out about a half a fid length or more and cut it at the spot where you initially grabbed.

Then, splay out the core strands and cut a taper into them. Once they are tapered, milk the cover over the tapered core. Note: Tapering is important. If not tapered well, the core will have an abrupt end to it inside the cover, which will create a weak spot in the line.

Step Seven: The Final Bury (FIG: 15,16,17,18) The last step in the splice is to suck the core and tapered cover inside the line.

Make sure that your line is securely anchored and then pull back on the line. While keeping constant pressure on the splice, milk the cover from your anchoring point back towards the splice and over the core and tapered cover. Try to keep slack out of the cover that forms the eye. If you end up with a bit of core showing, put a bar or handle of a hammer through the loop and give it a couple swift tugs to snug up the splice. Don’t be afraid to use force. If the splice is done properly, the core will not, and should not, be visible.

A double braid splice certainly isn’t the easiest thing to get perfect on your first try, so don’t get frustrated. Buy some extra line and practice until you are satisfied with the result.

When you get the hang of it, you’ll be looking all over your boat for places to add a splice and trading the service with fellow cruisers. Plus, learning to splice your own running rigging is immensely satisfying and can save you a few dollars at the boat yard.

Administrator

You might also like.

Problems with Paint Application Q & A

Dinghy Security

Winterizing Your Engine

Read the Summer-Fall Edition of Blue Water Sailing

Read the fall 2023 edition of blue water sailing, recent posts.

- Survey of the Week

- Lagoon Introduces New 60-Foot World-Girdling Family Cruiser

Please Visit Our Sponsor’s Webpages

- Media Advertising & Rates

Published by Blue Water Sailing Media, a division of Day Communications, Inc., Middletown, RI

Publisher & Editor: George Day

Blue Water Sailing Media publishes Blue Water Sailing magazine, Multihulls Today and other titles.

Cruising Compass Advertising Sales:

George Day, Newport, RI [email protected] 401-847-7612

- Excess 13 Cruising Cat Design Launch Refines the Brand’s DNA

- Fountaine Pajot Introduces New Sustainable, Affordable 41-Foot Cruising Cat

© 2014 Blue Water Media. All rights reserved. | Admin

- Competitions

- British Yachting Awards

- Southampton Boat Show

- Print Subscription

- Digital Subscription

- Single Issues

- Advertise with us

Your special offer

Subscribe to Sailing Today with Yachts & Yachting today!

Save 32% on the shop price when to subscribe for a year at just £39.95

Subscribe to Sailing Today with Yachts & Yachting!

Save 32% on the shop price when you subscribe for a year at just £39.95

Splicing: Double braid eye splice

In the second of a six part guide to splicing, sailing today takes a look at a double braid eye splice, a neat-looking but tricky splice..

Double braid lines with a polyester core are commonly used for a variety of low stretch running rigging roles such as halyards, reefing and control lines.

This splice is a real money saver as there are potentially a lot of these splices within a yacht’s running rigging. Don’t try your first time on used rope. New rope is more slippery and hasn’t yet been stretched and compacted between core and cover, so is much easier to work and splice. Also thicker rope is less fiddly to work, with more space between core and cover, so try your first splice on 12mm diameter or larger.

See our guide to a three-strand eye-splice here.

Hitch the line to something solid two or three metres back to stop the core and cover slipping beyond this point

Cut off melted end and using a marker pen, mark rope, (A), 25 times the rope’s diameter from its end

Mark (B) two and a half times the rope’s diameter from mark (A) towards the end. (B) marks one side of the eye’s neck

Lay the loop the size you want and make mark (C), where you want the other side of the splice’s neck, opposite (B)

Using the end of a fid, tease out the core of the rope at point (C). Mark the core, (D) at the point it came out

Pull the core out at (C) from the end of the rope. Align (D) with (B) and mark the core, (E), level with (A)

Insert a pulling fid about 3in (80mm) up the cover between (C) and the hitch. Tease it carefully down the rope between the core and cover, exiting the rope at (B)

Thread core and cover through any hardware you wish to include in the eye now, such as a snap shackle, then insert half of the core’s end into the fid eye

Carefully pull the fid back through, unhook the core from the fid eye and pull the core further through until D aligns with A and E aligns with B

Now insert the fid into the core 400mm from the rope end and exit at (E). Halve the cover, insert it into the fid eye and pull fid back through core

Cut the end of the cover at an angle. Scissors are easier than a knife. A nice long taper leaves a neater splice

Milk the core back over the cover so the tapered end of the cover pops back inside the core. It should look like this

Now pull hard on the eye and work the cover down and round the eye so there is no longer any core visible in the splice’s neck

Pull the eye tight, then pull 30mm of the core out and cut with a taper. Then work the cover back to hide the end of the core

The finished loop all neat, tidy and ready ready for use

info heading

info content

Buy the latest Sailing Today Follow us on Facebook Follow us on Twitter

No mobile device? Purchase directly on Zinio for your desktop!

RELATED ARTICLES MORE FROM AUTHOR

Anchoring Masterclass: How to Anchor like an Expert

Southampton Boat Show 2024: What to Expect

Steering by the Stars: A Guide to Celestial Navigation

Offering a wealth of practical advice and a dynamic mix of in-depth boat, gear and equipment news, Sailing Today is written cover to cover by sailors, for sailors. Since its launch in 1997, the magazine has sealed its reputation for essential sailing information and advice.

- Telegraph.co.uk

ADVERTISING

© 2024 Chelsea Magazine Company , part of the Telegraph Media Group . | Terms & Conditions | Privacy Policy | Cookie Policy

Splicing Instructions

Everything you need to know about splicing, what is splicing.

A splice is a way of terminating a rope or joining two ends of rope together without using a knot. Apart from being bulky and unsightly, even a correctly tied knot can cause significant loss of strength to a rope. At Marlow our splicing team have over 150 years of combined splicing knowledge and experience and we offer a splicing service to our trade and commercial customers for bespoke rope assemblies, slings and strops. For sailors and boat owners, we always recommend using your local rigging professional to splice and install your ropes. Find your local Marlow Rigging professional here.

For those wishing to splice their own ropes, we have produced a comprehensive splicing guide and range of splicing tutorials (scroll down to view) detailing a range of splicing methods. For hands-on splicing demonstrations, visit the Marlow stand at any of our shows and exhibitions throughout the year, or sign up to attend a Marlow Rope-Show held across the UK at sailing clubs once per month.

SPLICING TOOLS

When learning to splice, the right tools will make the job much easier. Below is a list of common splicing tools available through your Marlow dealer

Swedish fids are used primarily for 3 strand and multiplait splicing. They also aid Marlowbraid and D2 Racing splices.

Braid on Braid Fid Set – Selma fids are used primarily for doublebraid, D12 and D2 splices, but can also be used to aid 3 strand and marlowbraid splices.

Splicing Needles – Large and small used for Marlowbraid, D2 Racing. Can also be used for the doublebraid splice.

Excel Control Splicing needle – Used primarily for Excel Control and Excel D12 2.5 and 3mm.

Other tools and equipment – Sharp knife and/or scissors, tape measure, permeant marker pen, splicing (or insulation type) tape, strong point on your work bench, hot knife or flame for sealing the rope.

View our range of Splicing Accessories

Splices vs knots.

Splices: Most Marlow ropes can be spliced, this is normally the preferred method of termination. A good splice using the recommended method should not reduce the strength of a rope by more than 10%.

Knots: A knot will reduce the strength of the rope, sometimes very significantly. This loss is caused by the tight bends and compression found in any knot. The amount a rope will be weakened will depend on the knot, type of rope and the material from which it is made but can be up to 60%

Eye Sizes: Wherever possible the angle formed at the throat of a splice when it is loaded should be 30 degrees or less. This means that the length of the eye when flat must be at least 2.7 times the diameter of the object over which the eye is to be used and the distance from the bearing point to the throat when in use should be at least 2.4 times the diameter. Some materials like Aramids and HMPEs (Dyneema) will require a larger eye with an angle at the throat of 15 degrees or less.

SPLICING TUTORIALS

D2 covered eye splice.

D2 Covered Eye Splice – D2 and V2

Used for core dependent rope constructions such as D2 Racing, V2 etc. Designs where the core contributes most or all the strength and the cover provides protection to the rope.

Skill rating: Advanced 4/5

Locking Eye Splice – one end free

A popular starting splice great for beginners and one that is most common for locking Dyneema splices. This versatile splice can be applied in all applications where a lock is required.

Skill rating: Beginner 2/5

EXCEL control Continuous Loop Splice

Control Line End-to-End – Control Line.

The Excel Control Line Continuous Loop splice is specifically designed to make endless loops useful for kicker, cunningham and outhaul systems. Marlow’s Control Line has a tough, strong cover that takes much of the load bearing duties and a small polypropylene core that is designed to be sacrificed in this very neat end-to-end slice.

EXCEL R8 Taper

Excel R8 Taper – Excel R8

A Taper splice is useful in areas of rope that don’t require handling, for reducing friction and when needing to change the diameter of the line. Marlow’s high performing Excel R8 is the perfect rope for this type of splice available in 4-8mm diameters either working as a halyard or high performance sheet working well in ratchet blocks.

Skill rating: Intermediate 3/5

How to make a Soft Shackle

Soft Shackles are a great skill to master and they can be made in all shapes and sizes suitable for a variety of applications and fastenings. This quick and easy tutorial will guide you step by step.

If you are new to diamond knots, this part may take a bit of practice, however, the splice is quick and easy. Made with Dyneema, Marlow Soft Shackles have incredible breakload strength and are a worthy addition to your climbing or sailing kit, for use at home, outdoors or wherever you may venture.

Skill rating -Splice 2/5 | Diamond knot 4/5

Double Braid Splice

Doublebraid heat set rope combines industry-leading strength and stretch resistance with a flexible, user-friendly feel. Ideal for yacht sheets and splicing, its heat-treated design minimises stretch for both high-load and everyday use. This all-around rope offers exceptional performance.

With easy splicing removes the need for bulky knots which also reduce a ropes strength.

Our Membership

Marlow Ropes

Marlow Ropes Ltd, Ropemaker Park, Diplocks Way, Hailsham, East Sussex BN27 3GU UK

Connect with us

We use cookies on this site to enhance your user experience. for a complete overview of the cookies used, see our cookie policy ., welcome to marlow ropes.

If you’re looking for information about Marlow Ropes in the USA, please select below.

29th Jan 2021

How To Splice Double Braid Line (In Only 9 Steps)

1. Tie a slipknot about 15 feet from the bottom of the line, next loop it over a winch to hold it. Mark the line one fid-length from the end.

2. Form your loop to your preferred size and place a second mark opposite from the first.

3. Use a small fid to separate the strands of the cover at the second mark and pull it out! Lay the cord and cover beside each other.

4. Make your third mark at the core where it comes out of the cover and pull out a few feet more. Now you can place your fourth mark on the core two-thirds of a fid length from your third mark. This is where you will insert the cover into the core.

5. Wedge the end of the core into the hollow end of a fid that is sized to fit the diameter of the core. Next, push your fid into the cover at the first mark and work it down so that it pulls through the cover 1-2 inches past where the core exists.

6. Pull about 6 inches of the core out of the hole and begin to form your loop. Wedge the end of the cover into the fid and feed it into the core at the second mark. Push it down one complete fid length before pulling it out.

7. Starting from around 4 inches from the end, use a small fid to pull about 8-10 random strands from the cover before trimming with scissors.

8. Pull on the end of the exposed core as you push the junction of the core to the joint.

9. Last but not least, work the cover back up the line until the exposed core with the cover pops back into the line. Pull a little on the remaining core outside the line, trim, then tug on the eye to pull the end back inside the core.

- #double braid line

- #double braid rope

- #double braid splice

- #rope splicing

Newsletter Signup

Subscribe to newsletter emails for information on new products and coupon codes!!

IMAGES

VIDEO

COMMENTS

Samson recommends splicing as the preferred rope termination method. Knots can significantly decrease a rope's strength while, in most cases, splicing maintains 100% of the specified rope strength. This makes splicing a more reliable and durable option for critical applications. Splice terminations are used in all our ropes to determine new and ...

Learn how to splice a double braid polyester rope for sailing or other purposes. Watch the video tutorial and follow the easy steps.

8. Starting about 4 inches from the end, use a small fid to pull out about 8-10 random strands from the cover before trimming them off with scissors. This creates a neat splice with a taper. 9. Pull on the end of the exposed core as you massage the junction of the core to cover the joint. 10.

Cut them all off flush with the cover. Then make Marks 1, 2 and 3 as per the Jamestown instructions. Put the folded end of your homemade fid into the center of the core at Mark 3 and out at Mark 2. Thread the tapered end of the cover through the "eye" of the fid. Pull the fid back out through Mark 3 until Mark A on the cover (the mark just ...

BoatUS Magazine associate editor Mark Corke shows you how to splice double braid line. To add a loop or eye to double braid line on your boat, you need a len...

English Braids is looking to deliver the best possible support for all yachtsmen looking to maintain their own products. This video clearly demonstrates the ...

The essential tools for completing a double braid splice are: a length of new double braid line, a set of Samson Aluminum Tubular Splicing Fids (or similar), an awl or marlinspike, a sharp knife, cutting board, sharp scissors, masking or Marlow tape and a black Sharpie (silver if marking black line). Note: Do not splice used line; even if it ...

Other tips and tricks for splicing rope for milking the cover in this video. Splicing modern braided ropes of super fibres is quite fun and easy to learn. Premiumropes has uploaded various splicing tutorials, such as eye-splices, soft shackles, taper sheets or make a continuous furler line. Make sure you have enough space to work and an ...

Double braid lines with a polyester core are commonly used for a variety of low stretch running rigging roles such as halyards, reefing and control lines. This splice is a real money saver as there are potentially a lot of these splices within a yacht's running rigging.

Know-how: Easy Eye Splicing. Roger Hughes. Updated: Jan 22, 2024. Original: Sep 1, 2022. The new "splice" was put through its paces on an industrial quality test bed. For the record, I will be the first to admit that a professionally executed reverse-tuck Class 1 eye splice on modern braided line adds an air of proficiency and seamanship to ...

Double Braid Splice. Doublebraid heat set rope combines industry-leading strength and stretch resistance with a flexible, user-friendly feel. Ideal for yacht sheets and splicing, its heat-treated design minimises stretch for both high-load and everyday use. This all-around rope offers exceptional performance.

sliding the slack back from the knot towards the splice. Milk the cover from the crossover around the radius of the eye to the throat at "B" and pull that leg sharply with a spike to help seat the splice. Flex and/or hammer the splice section to loosen the fibers. Seize or cross-stitch the eye to finish the splice.

loosen and lubricate the fibers and make the splice easier to perform. Through use and exposure to the elements, the fibers in a used rope have probably lost some of their original strength. In addition, some shrinkage has probably occurred making this splice the most difficult to perform. General Splicing 3 Fid Lengths 3 Single Braid 4

Note: This splice is not suitable for core-dependent double braid constructions (Double Braid Class II). For Double Braid Class I products over 2" (48mm) in diameter, please see the special instructions included below. Tape end to be spliced with 1 thin layer of tape. Then measure 1 tubular fid length or 2 wire fid lengths from the end of the

SUBSCRIBE DIRECTLY with us so you never miss an episode: https://www.riggingdoctor.com/subscribeSplicing double braid line might seem complicated and overw...

My tool in this photo is indicating where the joint is going. (9) At the joint selected, get behind the core again. (10) Pull a length of core out of the length of the rope. It comes out easily. Note the 'fat' look of the cover on the long part of the rope as compared to the loop. Keep the loop snug.

1 fid length plus another short section Short section of fid. le Braid Class I Back Splice4. utting the cover inside coreInsert f. d into core at Mark 2. Slide fid through and out at Mark 3.Pinch taped en. of cover, jam it tightly into x hollow end of fid. Hold core lightly at Mark 3, place the pusher point into the taped end,

1. Tie a slipknot about 15 feet from the bottom of the line, next loop it over a winch to hold it. Mark the line one fid-length from the end.2. Form your loop to your preferred size and place a second mark opposite from the first.3. Use a small fid to separate the strands of the cover at the second mark and pull it out!

General Splicing Instructions. Adjustable Slings - Backsplice - 10015105. Industrial Double Braid Eye Splice - 10017200. Single Braid Eye Splice - 10015101. High Performance Single Braid Splice - 10015112. End-for-End Single Braid Splice - 10015102. End-for-End Single Braid Splice - 10015102. Yale Whiplock - 10017500.

The only reference devoted entirely to splicing today's ropes. The Splicing Handbook includes step-by-step illustrations and explanations for the most useful and popular splices in traditional twisted and modern braided ropes, and it covers every kind of splicing project you are likely to encounter, including modern cordage such as Spectra; mainstream rope materials such as Dacron and nylon ...

Rope: P-Classic. Eye splice in Rope: Eight -strand mooring . Download the Premium Ropes App with splicing instructions:. Step 1- Beginning the Splice. Measure 14 crowns (or twists) from the end of the line (18 crowns for a tapered splice). Mark this location with a temporary wrap of 6 Dec 2012 Step-by-step instructions for making an eye splice.

We would like to show you a description here but the site won't allow us.

994.MoSCoW Prioritisation1 IntroductionIn an Atern project where time has been fixed, understanding the relative importance of things is vital to. making progress and keeping to deadlines. Prioritisation can be applied to requirements, tasks, products, use cases, us. r stories, acceptance criteria and tests. MoSCoW is a techn.