- Boat Accessories

- Where to Buy

Special until September30th: 20% off Git-Rot (all sizes). Use Code SEPT24 at checkout. *restrictions apply

Free ground shipping in the Continental US for any orders over $150!

DIY Boat Repair – 5 Common Problems & Solutions...

Diy boat repair – 5 common problems & solutions.

You have a boat to repair. But you’re not sure that you’re ready to shell out hundreds or even thousands of dollars to an expert before you know if you can handle the boat repairs yourself. That’s why we’ve put together a list of five common DIY boat repair solutions that could allow you to keep your boat functioning at its best.

Problem #1: A Hazy Gel Coat

Liquid LifeSeal® Sealant 5.2 fl. oz. Clear

Stainless Steel Cleaner 16 fl. oz.

Related blogs, updated how to use “git”-rot.

**This is an update to a previous post, “How to Use “Git”-Rot””. The presence of wood rot can ruin any […]

Thanksgiving Trivia!

Happy Thanksgiving! Thanksgiving is one of America’s oldest and most loved holidays. Although the story is steeped in a dark […]

Detailing Your Boat

On a warm summer day with the sun shining, there’s no better way to spend your time than by hitting […]

All products proudly made in the usa

Yachting Monthly

- Digital edition

Boat maintenance: the 55-point skipper’s checklist

- Katy Stickland

- April 27, 2021

The ultimate boat maintenance checklist to make sure your yacht is ready for launch and the start of the sailing season

Check your rudder for hairline cracks or damage

Boat maintenance: Mast & Rigging

Check all your standing rigging connections. Credit: Colin Work

- The mast cap is out of sight, out of mind 99% of the time, but serves multiple functions: backstay, forestay, cap shrouds, radio antenna, nav lights, halyard sheaves. Rotate mast and boom sheaves to check they are not misaligned or worn by a bad halyard lead. Lubricate sheaves with WD40 or silicone grease.

- Spreaders, gooseneck, mast heel, kicker, mainsheet and topping lift connections all need checking for wear, damage or corrosion.

- Check for galvanic corrosion between different metals.

- Check electrical connections, deck and spreader lights.

- Wax mast tracks and luff grooves with candle wax or Teflon spray.

- Standing rigging: Look for areas of wear or stranding on the wire. Check mast tangs, T-ball joints and rigging screws.

- Wash furling drum and swivel and check they move freely. It’s common for the top swivels to become stiff and sometimes seize, which can compromise the forestay wire.

- Running rigging: check for chafe and that the shackles aren’t seized. Sheets, halyards, warps: wash in fresh water to get rid of salt and grime.

- Deck winches : strip down, wash parts in paraffin, wash off with soapy water and lightly regrease .

- Windlass : if manual, check it’s working, clean and tighten. For powered versions check foot switch for water, clean and use Vaseline on the connections.

- Anchor chain : Re-mark lengths if faded, or add chain markers. Check for condition and wear.

Head, bilge & gas

Check bilge pumps it might sound ok but is it actually attached to a hose?

- Check impeller on bilge pumps and grease with water pump grease only (Vaseline will rot impellers)

- If you have an automatic bilge pump, check float switches work.

- Dry bilges thoroughly then if water appears after relaunch you’ll know you’ve got a leak.

- Fill water tank and add purifier such as Puriclean or Milton

- If the pump on the heads is stiff look to service and lubricate with silicon grease.

- If you have a gas sensor, check it works.

Boat maintenance: Below waterline

Hull and skin fittings.

Check jubilee clips for rust. Credit: Bob Aylott

- Most vessels have DZR (dezincification-resistant brass) seacocks. Look for any signs of corrosion on the skin and tail joints, which are common points of failure.

- Ensure all valves are greased.

- All hoses should be double-clipped. Check jubilee clips for rust . Do you have wooden plugs attached in case of emergency?

- Check skin fittings are free of blockages/ growth or antifouling.

- Check anodes have plenty of life . Don’t forget prop shaft and saildrive anodes.

- Check leading, trailing and lower sections for damage or hairline cracks.

- Check for play in bearings, stock or quadrant. Movement should be minimal. Grease steering cable.

- Check for stress cracks or movement internally and externally – especially at the keel root and around the internal framing or matrix, and around fastenings and backing washers.

Prop shaft & stern gland

- To check bearings, grasp prop in both hands and try moving it up and down and from side to side. There should be little, if any, movement – no more than 2mm.

- Check P-bracket for stress cracking from misalignment or damage.

- Stern gland packing. Many yachts have some form of deep-seal arrangement that has a service life of around seven years. Those that have a proper stuffing gland will need to be greased to prevent drying out and getting brittle. The gland may need pulling down or repacking at some point.

- If you have a saildrive, check the condition of the seal and the metal ring that holds it in position. Again, note the seals have a life expectancy of between five and seven years depending on manufacture.

Boat maintenance: Mechanics

Check all filters

- If you didn’t change the oil when you laid up, change it now.

- Change fuel filters.

- Remove rags stuffed in outlet pipes from winterisation.

- Impellers – if removed at lay-up – reinstall with a smear of water pump grease.

- Reinstall the engine belts and check tension: there should be no more than half an inch of play.

- Check oil levels. Check durability of the gaiter seal. Check rubber faring and reseal if necessary.

- Change internal engine anode.

- Check engine mount is secure.

- Check diesel tank for water from condensation . Drain off or replace fuel. Add an appropriate biocide to help kill off diesel bug .

- Check inaccessible wiring, such as bonding wires from the anode and earthing wires from the starter motor. Clean the terminals and smear them with Vaseline or silicone gel.

Batteries and electrical systems

- Check electrolyte level if yours is an open lead acid battery; tighten battery securing straps and make sure vent for gases is clear. Clean terminals and coat with Vaseline. For sealed batteries, check the condition of indicator light, or other charge indicator.

- Switch on instruments and use backlighting to help reduce any condensation.

- If the anode looks serviceable for another season, check bonding and wires. If they haven’t worn at all they may not be working so check Ohm resistance max 0.2 from propeller to anode.

- Check for chafe, wayward stitching and tears. Do you carry a sail repair kit?

- Take to a sailmaker if the sacrificial strips is worn out.

Make sure your navigation apps are up to date

- Update charts from Notice to Mariners .

- For electronic charts, check with your supplier how to update. New chartplotters can connect to WiFi, or you may need to connect the chart chip to your PC at home and download the update.

- Download operating software updates for your chartplotter and instruments.

- Make sure your subscriptions for navigation apps on phone and tablets are up to date with the latest charts.

- Check age of hoses. If they are over five years old, they should be replaced. Check for kinking or wear in gas hosepipes. If in doubt, replace.

- Check hose clips are tight. Hoses behind cookers should be armoured.

- Check thermal cut outs on hob, grill and oven work.

Harness/lifelines

- Check stitching and get repairs done by a sailmaker if necessary.

- Jackstay and Danbuoy lines: check condition and points of security.

- If you have the traditional type, check the bulb, battery and that it actually works. The new types have various ways of testing, and all have an expiry date.

Lifejackets

Is your lifejacket fit for purpose and in good condition? Credit: Theo Stocker

- Inflate using mouth tube. Leave inflated overnight to check for leaks .

- Wash with fresh water

- Weigh cylinder and check lights if fitted.

Stanchions/lifelines

- Check stanchions and make sure lifelines are still suitably secured at each end and cords and pins are in good order.

- Watch out for wire failing if you have plastic sheathing.

- Make sure these are in date, in a watertight container and are easy to reach. It’s worth having gloves and goggles to hand too.

- Make sure these are in date and registered with the correct contact details.

- Ensure this and the hydrostastic release are within the service date, and you are aware of its contents .

- If its secured with a rope, consider if you could release it in an emergency with ease.

- Make a grab bag up with essentials

Enjoyed reading Boat maintenance: the 55-point skipper’s checklist?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

- CREATE AN ACCOUNT

- Boat Cover Finder

- Bimini Top Finder

- Boat Propeller Finder

- Engine Parts Finder

- Anchor & Dock

- Watersports

- Clothing and Footwear

- Engine Parts

- Cabin and Galley

- Covers and Biminis

- Electronics

- Paint and Maintenance

- Pumps and Plumbing

- Anchor Chains & Ropes

- Boat Fenders

- Boat Mooring

- Boat Protection

- Dock Storage & Protection

- Ladders, Steps, & Platforms

- Top Sellers

- Fishing Rods

- Fishing Reels

- Fishing Rod & Reel Combos

- Fishing Tools & Tackle Boxes

- Fishing Line

- Fly Fishing

- Fishing Bait & Fishing Lures

- Fishing Rod Holders & Storage Racks

- Fish Finders, Sounders & Sonar

- Trolling Motors

- Fishing Nets

- Fishing Downriggers & Acessories

- Fishing Outriggers & Acessories

- Fishing Kayaks

- Fish Cleaning Tables

- Inflatable Rafts

- Paddle Boarding

- Paddles & Oars

- Wakeboard, Wakesurf & Ski

- Wakeboard Towers

- Tow Ropes & Handles

- Life Jackets & PFDs

- Snow Sports

- Roof Racks, Carriers, Dollies

Men's Clothing

- Accessories

Men's Footwear

- Atheltic Shoes

- Water Shoes

Women's Clothing

- Dresses & Skirts

Women's Footwear

- Fuel Systems

- Sacrificial Anodes & Zincs

- Generator Parts

- Inflatable Boats

- Propeller Parts & Accessories

- Boat Manuals

- PWC Parts & Accessories

- Fishing Boat Seats

- Offshore Boat Seats

- Ski Boat Seats

- Pontoon Boat Seats & Furniture

- Boat Seat Pedestals & Hardware

- Boat Seats by Manufacturer

- Boat Tables & Hardware

- Boat Seat Covers

- Boat Seat Vinyl

- Floating Boat Cushions

- Barbeque Grills

- Boat Drink Holders

- Cabin Accessories & Hardware

- Boat Ventilation

- Interior & Cabin Lighting

- Marine Teak Products

- Carbon Monoxide & Smoke Detectors

- Binoculars & Telescopes

Boat Bimini Tops

- Bimini Top Accessories

- Pontoon Bimini Tops

- Other Biminis

- RV & Trailer Covers

- Boat Shrink Wrap & Accessories

- Boat Shelters

- Boat Covers

- Boat Cover Accessories

- Boat Lift Canopy Covers

- Other Covers

- Boat Wiring & Cable

- Marine Batteries & Accessories

- Marine DC Power Plugs & Sockets

- Marine Electrical Meters

- Boat Lights

- Marine Electrical Panels & Circuit Breakers

- Power Packs & Jump Starters

- Marine Solar Power Accessories

- Marine Electrical Terminals

- Marine Fuse Blocks & Terminal Blocks

- Marine Switches

- Shore Power & AC Distribution

- Marine Audio & Video

- GPS Chartplotters & Accessories

- Electronic Navigation Charts & Software

- Digital Instruments

- Display Mounts

- VHF Radios & Communication

- Marine Radar

- Auto Pilot Systems

- Action Cameras

- Fiberglass & Epoxy Boat Repair

- Boat Paint & Varnish

- Marine Adhesives, Sealant, & Caulking

- Marine Engine Maintenance

- Boat Cleaners & Waxes

- Boat Cleaning Supplies

- Fresh Water Boat Systems

- Bilge Pumps

- Marine Plumbing Parts

- Wash Down Pumps

- Livewell Aerator Pumps & Live Bait Wells

- Toilet & Waste Pumps

- Marine Pump Replacement Parts

- Tires, Rims, & Hub Kits

- Boat Trailer Winches

- Boat Motor Supports & Transom Savers

- Boat Trailer Guides & Rollers

- Boat Trailer Fenders

- Boat Trailer Lights

- Boat Trailer Hardware

- Boat Trailer Jacks

- Boat Trailer Brakes & Axles

- Boat Trailer Tie Downs

- Couplers, Mounts, Hitches, & Locks

- Boat Deck Harware

- Marine Nuts, Bolts, & Screws

- Boat Handles, Pulls, & Rings

- Prop Nut Kits & Hardware

- Boat Cabin Hardware

- Marine Fasteners

- Boat Windshield Parts

- Boat Tubing & Rails

- Boat Mirrors

- Marine Tools & Tool Kits

- Boat Lettering

- Women's Clothing Deals

- Men's Clothing Deals

- Fishing Deals

- Anchor & Dock Deals

- Electrical Deals

- Electronics Deals

- Paint & Maintenance Deals

- Pumps & Plumbing Deals

- Boat Seats Deals

- Trailering Deals

- Camping & RV Deals

- Dealer Login

- Forums Login

- Search forums

- The iboats forum moderators are excited to announce that at this time it appears the iboats forums posting pictures function is working once again. Though we cannot promise for how long, we're hoping for indefinitely.

Boating Forum - iboats Boating Forums

Forum rules and guidelines.

- May 17, 2018

General Boating/Outdoors Activities

Boat topics and questions (not engine topics).

- Yesterday at 5:06 PM

Trailers and Towing

- Tuesday at 5:15 PM

Prop Questions and Topics

- Yesterday at 6:49 PM

Boating Activities, Rendezvous and Destinations

- Wednesday at 6:18 AM

- Scott Danforth

iboats Boating Cartoon

- Jul 28, 2024

- Sep 3, 2024

- Sep 9, 2024

Inflatables and RIBs

- Wednesday at 6:34 PM

PWC (Jetskis, Waverunners, etc.)

- Sep 13, 2024

Towables and Stand Up Paddleboards

- Aug 31, 2024

Wakeboarding, Wakesurfing, and Wakeskating

- Jul 3, 2024

- Water Skiing

- sangerwaker

Boating Safety

- Yesterday at 3:30 PM

Boat Repair and Restoration

Boat restoration, building, and hull repair.

- 23 minutes ago

Steering and Controls

Electrical, Electronics, Audio and Trolling Motors

- Yesterday at 6:34 PM

Completed Boat Projects

- Jan 31, 2018

Engine Repair and Maintenance

Engine frequently asked questions (faq).

- Feb 22, 2024

Non-Repair Outboard Discussions

- Wednesday at 11:54 AM

Johnson & Evinrude Outboards

- Yesterday at 11:24 PM

Mercury & Mariner Outboards

Yamaha & suzuki outboards.

- Yesterday at 10:16 AM

Force & Chrysler Outboards

- 44 minutes ago

- jerryjerry05

Lehr Propane Outboard Engines

- Jul 14, 2022

Honda & Tohatsu/Nissan Outboards

- Wednesday at 1:13 PM

Other Outboard Brands

- Yesterday at 9:28 PM

Non-Repair I/O and Inboards

- Monday at 10:46 AM

Mercury MerCruiser Sterndrives & Engines

- 18 minutes ago

- 1985 Century Mustang

Volvo Penta I/O & Inboard Gas Engines & Outdrives

- Yesterday at 12:51 PM

OMC I/O & Inboard Engines & Outdrives

- Yesterday at 12:29 PM

Other Brands of I/O & Inboard Engines & Outdrives

- Sep 8, 2024

Diesel Marine Engines

- Saturday at 7:12 PM

- Freshwater Fishing

- Saturday at 6:28 AM

- Saltwater Fishing

iboats Forum and Website Issues

- Sep 11, 2024

Non-Boating Technical Topics

- Tuesday at 12:35 PM

- DeepCMark58A

Stupid Human Tricks While Boating/Fishing

- Wednesday at 1:14 PM

- redneck joe

Dockside Chat

- 40 minutes ago

Owners Groups By Manufacturer View our Forums by Boat Manufacturer.

- Achilles Inflatable Boats

- Action Craft Boats

- Advantage Boats

- Albemarle Boats

- Aloha Pontoon Boats

- Alumacraft Boats

- Angler Boats

- Apreamare Boats

- Arima Boats

- AristoCraft

- Arkansas Traveler

- Arrow Glass

- Avalon Pontoons

- Azure Boats

- Baha Cruiser Boats

- Baretta Boats

- Bass Cat Boats

- Bayliner Boats

- Beachcraft Boats

- Bennington Boats

- Bentley Pontoon Boats

- Bertram Yacht

- Blue Fin Boats

- Blue Water Boats

- Blue Wave Boats

- Bomber Boats

- Bonito Boats

- Boston Whaler

- Bristol Boats

- Bryant Boats

- Bullet Boats

- Cabo Rico Yachts

- Cajun Special Boats

- Calabria Ski Boats

- Campion Boats

- Cape Horn Boats

- Caravelle Boats

- Carolina Skiff

- Carri Craft

- Carver Yachts

- Catalina Sailboats

- Cathedral Thunderbird Boats

- Celebrity Boats

- Centurion Boats

- Century Boats

- Challenger Boats

- Champion Boats

- Chaparral Boats

- Charger Boats

- Checkmate Boats

- Cherokee Boats

- Chris Craft

- Cobalt Boats

- Cobia Boats

- Concept Boats

- Concord Boats

- Contender Boats

- Correct Craft

- Crest Pontoon Boats

- Crestliner Boats

- Crownline Boats

- Cruisers Yachts

- CW Hood Yachts

- Donzi Marine

- Doral Boats

- Duracraft Boats

- Ebbtide Boats

- Edgewater Boats

- El Pescador

- Everglades Boats

- Feather Craft

- Fiberform Boats

- Fisher Boats

- Fishrite Boats

- Flotebote-Flote Dek

- Forester Boats

- Formula Boats

- Fountain Boats

- Four Winns Boats

- Galaxie of California

- Gambler Boats

- Gekko Sport Boats

- Glen-L Plan Built

- Glacier Bay Boats

- Glass Magic

- Glassmaster Boats

- Glasstream Boats

- Glastron Boats

- Godfrey Marine

- Grady-White Boats

- Grand Banks

- Gregor Boats

- Grumman Boats

- Gulfstream Boats

- Harris FloteBoats

- Harris-Kayot Boats

- Hatteras Yachts

- Hewes Boats

- Hiliner Marine

- Hobie Cat Boats

- Homemade/Homebuilt

- Hurricane Deck Boats

- Hydra Sports Boats

- Hydrostream

- Invader Boats

- Javelin Boats

- Kenner Boats

- Key Largo Boats

- Key West Boats

- Landau Boats

- Larson Boats

- Livingston Boats

- Luhrs Boats

- Tuesday at 5:28 AM

- Marada Boats

- Mainship Trawlers

- Malibu Boats

- Manitou Boats

- Mariah Boats

- Mastercraft Boats

- Maxum Boats

- McKee Craft Boats

- Meridian Yachts

- Mirage Boats

- Mirrocraft Boats

- Monark Boats

- Monterey Boats

- Moomba Boats

- Nauticstar Boats

- Nitro Boats

- Old Town Canoe

- Parker Boats

- Penn Yan Boats

- Pioneer Boats

- Polar Boats

- Polar Kraft Boats

- Portland Pudgy

- Powerquest Boats

- Premier Marine

- Princecraft Boats

- Pro Sport Boats

- Pro-Line Boats

- Procraft Boats

- Pursuit Boats

- Rampage Yachts

- Regal Boats

- Renken Boats

- Rinker Boats

- Riviera Marine

- Robalo Boats

- Orlando Clipper

- Yesterday at 11:11 AM

- Sailfish Boats

- Sanger Boats

- Sanpan Boats

- Scotty Craft

- Scout Boats

- Sea Boss Boats

- Sea Cat Boats

- Sea Chaser Boats

- Sea Hunt Boats

- Sea Nymph Boats

- Sea Ray Boats

- Sea-Pro Boats

- SeaArk Boats

- SeaDoo Boats

- Sealine Boats

- Seastrike Boats

- Seaswirl Boats

- Shallowcraft

- Shamrock Boats

- Shearwater Boats

- Sidewinder Boats

- Sierra by Northport

- Silver Marine Boats

- Silverline Boats

- Silverton Yachts

- Skeeter Boats

- Ski Centurion Boats

- Ski Supreme

- Skinny Water Boats

- Smoker-Craft Boats

- Sonic Usa boats

- Sport-Craft Boats

- Stamas Yachts

- Starcraft Boats

- Steury Boats

- Stingray Boats

- Stratos Boats

- Sugar Sand Marine

- Sun Chaser Boats

- Sun Tracker

- Sunbird Boats

- Sunseeker Yachts

- Supra Boats

- Sylvan Boats

- Wednesday at 4:42 AM

- Tahoe Boats

- Tempest Boats

- Terry Boats

- Thunderbird

- Thunderbolt

- Thundercraft Boats

- Tiara Yachts

- Tracker Boats

- Triton Boats

- Trophy Boats

- Twin Vee Boats

- Vanguard Boats

- Velocity Boats

- Venture Boats

- Walker Bay Boats

- War Eagle Boats

- Weldcraft Boats

- Wellcraft Boats

- Winner Boats

- Woodson Boats

- World Cat Boats

- XPress Boats

- Yamaha Jetboats

- Zodiac Boats

- Aug 15, 2024

- Johnny Booth

iBoats Boating Forum Directory

- Mercury Outboards

- Johnson Outboards

- Evinrude Outboards

- Force Outboards

- Yamaha Outboards

- Mariner Outboards

- Suzuki Outboards

- Honda Outboards

- Chrysler Outboards

- Tohatsu Outboards

- Nissan Outboards

- Outboard Motors: non-repair

- Vintage Outboards

- OMC I/O, Inboard

- Volvo Penta

- Boat Propellers

- Boat Building and Repair

- Fiberglass Boat Repair

- Marine Electronics

- Boat Trailers and Towing

- Boating Topics and Questions

- Boating Activities and Destinations

- Boating Blunders

- Wakeboarding

- Aluminum Boats

- Bowrider Boats

- Center Console Boats

- Cruiser Boats

- Cuddy Cabin Boats

- Fishing Boats

- Fish and Ski Boats

- Pontoon Boats

- Boats (250+ Manufacturers)

Members online

- a70eliminator

- Bigcarp1289

Latest posts

- Latest: 1985 Century Mustang

- Latest: kcassells

- Latest: cam1399

- Latest: dingbat

- Latest: jerryjerry05

Forum statistics

Share this page.

- Yacht Painting

- Yacht Refits

- Expert Teak Deck Repair in Florida

- Faux Boat Painters

- Jacuzzi Boat Painters

- Marine Carpentry

- Fiberglass Repair

- Bottom Painting

- Expert Alexseal Painters in Florida

(954) 327-3009

Fiberglass Boat Repair Techniques: Quick and Effective Fixes

Understanding Fiberglass Boat Repair

With 20 years of boating experience , I’ve learned that maintaining the integrity of a fiberglass boat is essential. The repair process involves several crucial steps which require attention to detail and a systematic approach.

Firstly, assessing the damage is critical. Fiberglass boats can suffer from a range of issues, from minor scratches to major holes. As someone who’s handled many such repairs, identifying the extent of the damage dictates the repair strategy.

Here are the basic steps I follow:

- Inspect the affected area carefully to understand the depth and extent of the damage.

- Prepare the repair site by cleaning the area and removing any damaged or loose material.

- Sand the damaged area to create a rough surface for better adhesion of repair materials.

Next, selecting the materials is just as important as the repair technique itself. Epoxy resin is my go-to due to its strong adhesion and long-lasting repair qualities. Here’s a guide on basics of selecting repair materials .

Applying the repair materials involves layering fiberglass cloth and resin. The fiberglass cloth provides strength, while the resin, when cured, restores the integrity of the hull.

Remember, practice makes perfect. Working with fiberglass can be daunting, but with patience and care , a meticulously completed repair is indistinguishable from the original structure. Each repair I’ve completed over the years has reinforced my precision and skill, ensuring lasting results that keep my vessel seaworthy.

Materials and Tools Required

In my 20 years of boating experience, I’ve found that having the correct materials and tools is crucial for a successful and durable fiberglass boat repair. Knowing what to use will save you time and ensure the integrity of your boat’s structure.

Essential Materials

- Fiberglass Cloth: A foundational element for any repair, providing strength and stability to the damaged area. The quality of the cloth directly affects the repair’s resilience.

- Resin (Epoxy or Vinyl Ester): Acts as a binder for the fiberglass cloth. Epoxy resin is preferable for its strong bond and water resistance.

- Gelcoat: For aesthetic touches and to protect the repair from UV rays and water intrusion, gelcoat is applied as the outermost layer.

Recommended Tools

- Sandpaper (Various Grits): Starting with coarser grits for shaping and finer grits for finishing provides a smooth surface for repair.

- Acetone: Essential for cleaning the repair area and ensuring that contaminants do not compromise the bond.

- Brushes and Rollers: For applying resin evenly. Brushes are used for detail work and rollers for larger areas.

- Mixing Sticks and Cups: Necessary for preparing and mixing the resin before application. Accurate measurements are key to achieving the desired cure and bond strength.

Assessing the Damage

In my 20 years of boating experience, I’ve come to understand that thoroughly evaluating the type and extent of damage is critical before undertaking any repair work on a fiberglass boat.

Types of Damage

Structural Damage: This occurs to the supporting framework and influences the boat’s overall integrity. A cracked hull, for instance, compromises the vessel’s safety and needs immediate attention.

Cosmetic Damage: These are surface-level issues, such as gelcoat cracks and scratches, that do not affect the boat’s seaworthiness, but restoring the appearance is important for maintaining value.

Damage Assessment Process

Visual Inspection:

- Examine the hull and deck for any obvious signs of impact or wear.

- Look for hairline cracks, which could indicate more severe damage beneath the surface.

Tap Testing:

- Gently tap the fiberglass with a plastic hammer.

- An area that sounds hollow or different could be suffering from delamination or water intrusion.

Moisture Readings:

- Use a moisture meter to detect any water retention within the fiberglass.

- Higher readings signify potential problems with the laminate that could lead to further deterioration.

Assessing the damage with precision sets the stage for an effective and necessary repair. While smaller repairs may be DIY-friendly, significant structural damage often requires professional intervention.

Preparing for Repair

With 20 years of boating experience, I’ve learned that successful fiberglass boat repair starts with meticulous preparation. Whether you’re patching a small chip or mending a larger gash, setting the stage correctly is crucial for a long-lasting fix.

Surface Preparation

Before any resin or gelcoat is applied, the area must be clean and properly prepped. First , the damaged spot should be sanded down to remove any jagged edges and create a receptive surface for bonding. Then , washing the area with a dewaxing solvent is essential to eliminate any wax or mold release, which could compromise the repair. I’ve found that skipping this step can result in weak adhesion of the new material. Visit Repairing Fiberglass On Boats for a comprehensive guide on working with fiberglass.

Safety Measures

Fiberglass repair requires handling hazardous materials, so safety cannot be taken lightly. Always wear:

- Gloves : to protect your hands from sharp fiberglass strands and chemicals.

- Respirator mask : to avoid inhaling hazardous dust and fumes.

- Safety goggles : to shield your eyes from debris.

Moreover, maintaining a well-ventilated workspace is non-negotiable to dissipate fumes from resins and solvents. This minimizes the risk of respiratory issues and ensures a safer working environment.

Fiberglass Repair Techniques

With 20 years of hands-on boating experience, I’ve developed a deep understanding of fiberglass repair techniques that are essential for sustaining the integrity and appearance of your vessel. The key to successful repair lies in identifying the scale of the damage and employing the correct method.

Minor Repairs

Minor damages to a fiberglass boat, such as small scratches or chips, can often be repaired with simple DIY solutions.

- Materials Needed : For such repairs, you’ll need resin, hardener, fiberglass cloth, sandpaper, and a suitable gelcoat.

- Process : Begin by cleaning the area thoroughly and sanding down any rough edges. Cut the fiberglass cloth to size, mix the resin with hardener, and apply it to the affected area. Once the resin cures, sand it down to a smooth finish and apply the gelcoat for aesthetic appeal.

To illustrate, fixing a hairline crack would typically involve cleaning the area, applying a mixed resin, and laying down a piece of fiberglass cloth. After the resin has cured, I’d sand the area flush and then apply a gelcoat to match the boat’s original finish.

Major Repairs

For more significant damage, such as holes or structural weaknesses, the repair process is more complex and may require professional intervention. However, I’ve tackled such challenges myself when possible.

- Materials Needed : A list of materials includes thicker fiberglass matting or cloth, epoxy resin, a release agent, and reinforcing materials.

- Process : The area in need of repair must be ground away to remove any damaged material and to create a beveled edge where new material can be applied. Next, layers of fiberglass and resin are built up until they fill the area. It’s critical to ensure no air pockets are trapped, as this could compromise the repair’s integrity.

For example, repairing a hole in the hull involves placing a backing material behind the hole, then layering fiberglass and resin until the repair is level with the hull surface, finishing with sanding and gelcoat application. Each layer must cure properly before the next is applied, ensuring a bond as strong as the original hull.

By applying these techniques, I’ve been able to extend the lifespan of boats and maintain their value and performance.

Finishing the Repair

In my 20 years of boating experience, I’ve learned that achieving a flawless finish on a fiberglass repair is crucial for both aesthetics and the boat’s integrity. Accurate sanding, followed by meticulous buffing and polishing, are the final steps to ensure a repair blends seamlessly with the boat’s original surface.

First Pass: Coarse Grit. I start with a coarse-grit sandpaper to remove the excess cured fiberglass, working my way towards the repair margins. Care is taken not to gouge the surrounding area, which could require additional repairs.

Second Pass: Medium Grit. Once the high points are leveled, I switch to a medium-grit sandpaper. Gradual transitions are essential to avoid noticeable edges or low spots in the final product.

Final Pass: Fine Grit. To prepare for finishing, I use fine-grit sandpaper. This smoothens the surface further, removing any scratches left by coarser grains and creating a surface ready for polish.

Buffing and Polishing

Buffing Stage. After sanding, I buff the area with a rubbing compound to remove any fine scratches. This process requires a gentle touch and a steady circular motion to achieve a uniform shine without creating swirl marks.

Polishing Stage. The final step is applying a high-quality marine polish. This not only enhances the shine but also adds a protective layer against UV rays and saltwater. For the best results, I apply polish in thin layers, allowing each to dry before buffing it to a high gloss.

Gelcoat Application

In my 20 years of experience with fiberglass boats, I’ve learned that the key to a superior gelcoat finish lies in meticulous mixing and precise application methods. Ensuring the mix is correct and the application is smooth will greatly affect the longevity and appearance of the boat’s surface.

Gelcoat Mixing

Before applying gelcoat, it’s crucial to prepare the mix accurately. I always start with a clean mixing container to avoid contamination. Then, I add the gelcoat base, followed by a catalyst—typically methyl ethyl ketone peroxide (MEKP)—at a precise ratio, which is often around 2% of the volume of the gelcoat. Mix thoroughly for at least 2 minutes, ensuring a uniform color and consistency with no streaks.

Gelcoat Application Methods

When applying gelcoat, I use two main methods: brushing and spraying. Each has specific advantages, so I choose based on the repair’s nature and size.

- Ideal for small repairs or areas that are not easily accessible.

- Use a high-quality brush for an even coat and to avoid brush marks.

- Preferred for larger areas to achieve a more consistent finish.

- Requires a gelcoat spray gun and personal protective equipment to prevent inhalation of fumes.

Regardless of the method, it’s important to maintain a wet edge to avoid visible lines in the finish and apply multiple thin layers rather than one thick one to reduce the likelihood of sagging or running. After application, curing times can vary, but I usually wait a minimum of 24 hours before sanding or polishing.

Curing and Post-Cure Procedures

With two decades of handling boats, I’ve learned that meticulous attention during the curing and post-cure phases is critical for dependable fiberglass repair.

Curing Process

The curing process is when the resin hardens and bonds with the existing fiberglass. I ensure that the temperature is between 70-80 degrees Fahrenheit, as too cold or too hot can affect the cure. When I apply resin, I layer it with a catalyst, make sure the area is well-ventilated, and keep it free from dust. I use plastic film or PVA as a seal over the last resin layer to ensure a thorough cure without any tackiness.

Post-Cure Inspection

Once the resin has fully cured, my next step is a thorough inspection. I feel for imperfections such as bumps or air pockets. Any found imperfections are then addressed with gelcoat paste and allowed to cure fully. After it has cured, the patch should be sanded smoothly and polished to match the surrounding area, restoring the boat to its original condition.

Maintenance Tips

With my 20 years of boating experience, I’ve learned that regular upkeep and a proactive approach to maintenance can save you from costly repairs in the long run. Let’s dive into what I consider essential practices.

Routine Maintenance

Inspect and Clean: Every time I return from the water, I make it a practice to inspect my boat thoroughly for any signs of damage or wear, especially on the hull. I pay close attention to scratches or cracks that can worsen over time. After inspection, a thorough cleaning with soap and water helps identify any new issues that may have been obscured by dirt or debris.

- Simple Repairs: For minor scrapes that haven’t penetrated the gelcoat, I apply a marine polish to protect the area. It’s a simple but effective method to maintain the integrity of the fiberglass. However, if the damage is deeper, I make sure to apply a patch at the earliest opportunity to prevent water infiltration.

Preventive Measures

Regular Waxing: I ensure that twice a year, my boat receives a good layer of quality marine wax. This acts as a barrier against UV rays, salt, and pollutants that may harm the fiberglass. It’s an effective way to extend the boat’s aesthetic appeal and structural integrity.

- Storage and Cover: When not in use, I store my boat in a dry and shaded area. A sturdy cover is essential to protect it from the elements. I’ve learned that proactive covering minimizes the exposure to sun, moisture, and temperature fluctuations that can lead to fiberglass degradation.

Remember, a well-maintained boat ensures not just longevity but also safety and reliability. It pays to adopt a meticulous care routine.

Frequently Asked Questions

Drawing from my 20 years of boating experience, I’ve compiled a list of frequently asked questions relevant to fellow boaters looking to repair their fiberglass vessels. These inquiries cover the essentials of materials, procedures, and costs involved in keeping your boat seaworthy.

What type of epoxy is best for repairing boat hulls?

In my experience, marine-grade epoxy is the most reliable for repairing boat hulls due to its strong adhesion, resilience to water, and ability to bond with fiberglass. It’s crucial to select an epoxy that cures hard and can be sanded and painted over for a uniform finish.

What steps are involved in repairing large gelcoat damage on a boat?

Repairing large gelcoat damage typically involves cleaning the damaged area, removing any loose material, applying a gelcoat matching your boat’s current color, and then sanding it smooth. The repair area should be thoroughly dewaxed before applying new gelcoat. After curing, I always recommend polishing to restore shine and protect the repair.

How can you fix a serious gouge in a fiberglass boat’s surface?

To fix a serious gouge, I first clean the area with a dewaxing solvent, then fill the gouge with a fiberglass filler or resin. It’s important to apply the filler in layers and sand smoothly between applications. Once filled, the area should be finished with gelcoat, epoxy, or paint as necessary.

Is it possible to repair structural damage to a fiberglass boat by oneself, and what materials are needed?

Yes, it’s possible to manage structural repairs, but it requires careful planning and quality materials, including fiberglass mat, resin, and hardener. For internal structural damage, it may be necessary to use a thicker fiberglass mat for added strength when layering over the damaged area.

What is the average cost to repair a hole in a fiberglass boat?

The cost to repair a hole in a fiberglass boat can vary significantly based on the size and location of the damage, with DIY repairs typically ranging from $75 to $300 for materials. Professional repairs can escalate well into the thousands depending on the extent of the damage.

What are the most effective methods for fixing a leak in a fiberglass boat hull?

For fixing a leak in a hull, it’s effective to identify the source, dry the area, and then apply a marine-grade epoxy or fiberglass patch kit. The patched area must be adequately sealed to prevent future water ingress. In leaks where the damage is extensive or structural, professional assessment and repair are recommended for safety.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Keep in mind that we may receive commissions when you click our links and make purchases. However, this does not impact our reviews and comparisons. We try our best to keep things fair and balanced, in order to help you make the best choice for you.

As an Amazon Associate, I earn from qualifying purchases.

Vanquish Boats

500 Lewis Drive Carolina Beach, NC

+1 910-707-3599

© Vanquish Boats

ACTIVE STORM TRACKER Hurricane and Tropical Storm Information Learn more

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Install & Repair

Can You Handle These 5 Common Boat Repairs?

Advertisement

Every boat owner will encounter at least one of these problems — at an inopportune moment, of course! Here's how to deal with them.

You don't need to know how to fix everything that could go wrong aboard, but a few simple skills could mean the difference between enjoying a fun day on the water or being stuck at the dock. (Photo: Getty Images/Amnat Jonjum)

There are few recreational activities that provide more opportunities to channel your inner MacGyver than boating. The key to successfully overcoming these impromptu lessons on how your boat systems work is having a plan in place before they occur. Let's look at five situations all boat owners should be prepared for.

1. Replacing A Worn Or Broken Alternator Belt

That squeal coming from your engine compartment is likely your boat's way of saying the alternator belt needs replacing. A belt that's beginning to disintegrate will show signs of fraying or cracking, which can usually be seen while in place with a flashlight and hand mirror. The presence of belt dust (a black dust or residue) in the front of the engine is a common sign of belt deterioration. It's also a possible indication of wear due to a misalignment issue. If you notice this, your inspection should also include use of a straightedge to verify all pulleys are square.

When installing a new belt, start by studying the old belt's routing if the belt is intact and still in place. Simplify things even more by taking a few pics for reference prior to removal. If the old belt has self-destructed, verify routing of the new belt by consulting the engine manual.

Photo: Mark Corke

Removing an existing belt or replacing a broken one will typically involve loosening some component, such as the alternator, then retensioning and tightening it after the new belt is in place. Once installed, use your thumb to apply moderate pressure halfway between the pulleys. The new belt should deflect around 3/8-inch depending on the distance between the pulleys. Follow your engine manual for specific guidelines.

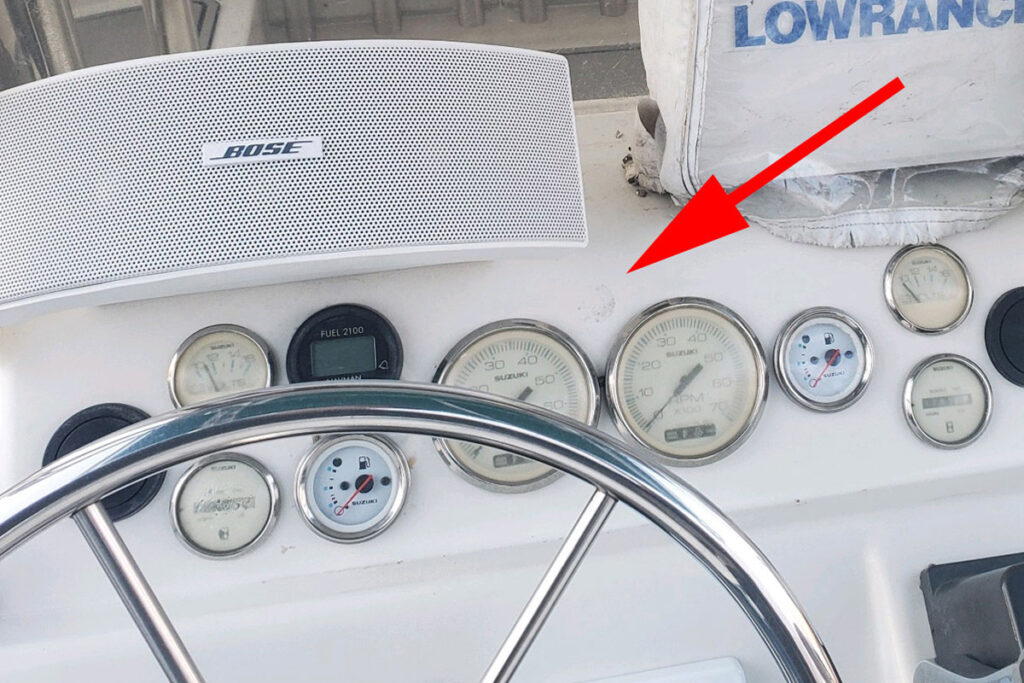

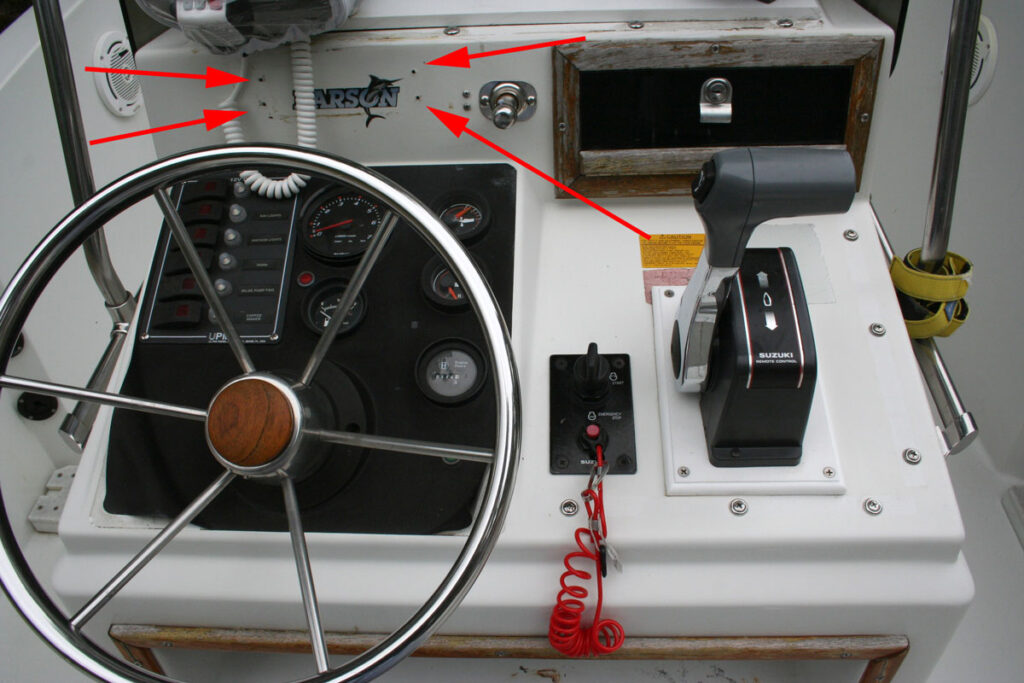

2. Troubleshooting Electronics Issues

What's the plan if your depth sounder blanks out while entering a questionable harbor, or the chartplotter bites the dust when heading out for a day of fishing? The first step in troubleshooting a piece of electronics gear or system is something you've hopefully done before the problem arises: read the owner's manual. A basic understanding of how a system functions and is installed (e.g., a block diagram) before you start troubleshooting is extremely helpful in recognizing and locating common problems. Most manuals will also have a basic troubleshooting section, which can help point you in the right direction.

When a piece of electronics gear fails to turn on, start by checking the power connection at the unit for looseness or corrosion. If your DC power panel has a volt meter installed, take a quick look to verify that it shows the correct voltage and that all required breakers are on.

For electronics that work intermittently or lose certain functions, check the remaining plugs or wire connections. These could also suffer from corrosion or may have vibrated loose over time. Sometimes problems can be corrected by simply disconnecting cable plugs and plugging them back in. The same is true for inline cable connections, which can loosen due to excessive movement or vibration if not secured or mounted properly. Trace the cable run as well, while looking for breaks or other damage.

Hopefully you won't encounter something that looks like this when you’re trying to track down the cause of an electronics issue. (Photo: Frank Lanier)

If a piece of electronics powers up but shows nothing on the display, start simply. Check the display brightness and contrast settings. These settings often get adjusted on purpose (to preserve night vision for example) or by accident to the point where the display is no longer visible under different lighting conditions. Other control features can also generate what I call "operator-induced anomalies." If your radar fails to pick up targets, for example, verify you're on the correct range setting and that the gain/sensitivity features are adjusted correctly.

When it comes to no-power issues, if you've verified all connections are tight, yet the problem persists, it's time to break out the multimeter . Every boat should have one, particularly as basic units can be purchased for less than $10. Stay away from light pen-type voltage testers, however. They can tell you if there's voltage, but not how much — a critical troubleshooting flaw as many electronics fail to operate if the voltage drops below a certain level.

To check the power to a piece of gear, turn the unit off and disconnect the power plug or access the terminal strip where power is connected. Then verify that battery switches and breakers are in the on position.

Set the multimeter to the appropriate DC voltage test setting (typically 12 volts DC, but you'll need to verify this). Many of the higher quality digital meters will auto scale to the correct voltage, eliminating this step.

Next, measure the voltage by connecting the meter's negative probe to the equipment plug negative lead and positive probe to the positive lead. If you accidentally reverse the probes, a digital meter will simply display a negative reading. A voltage reading of "0" indicates no power is reaching the unit. Common causes include a tripped breaker, blown fuse, loose connection, or broken wire. One thing to note is a fuse that "blows" multiple times when replaced should be considered a symptom rather than the problem itself.

A low voltage reading indicates low battery voltage or possibly additional resistance in the line (for example, a corroded or faulty connection). Verify that the correct amount of power is leaving the breaker panel, then work your way toward the equipment to identify the problem. If the voltage shown at the meter is incorrect, verify the voltage at the battery is correct and proceed from there.

Another factor to consider is how steady or consistent the voltage is during equipment operation. Some electronics draw more power during certain operations. A good example is your VHF radio when transmitting versus receiving. While you may have a "full" 12 volts at the power plug when the radio is disconnected or simply turned on, that voltage can drop well below a usable level when the radio is keyed to transmit. This is often due to a weak battery or possibly a corroded connection. Monitor your DC panel volt meter, or use your volt meter, while keying the radio to see if the voltage drops. (Whenever working around wires or electricity — even 12-volt DC — be aware of the issues and dangers, and the possibility of AC current in the proximity of where you're working. Avoid it if you're not familiar with what you're doing.)

Basic Repair Rules

- Be prepared. Carry the proper tools, manuals, and parts for your systems.

- Check the simplest things first, especially the last thing you may have adjusted or fixed. You may have inadvertently caused the current problem.

- Take your time.

- Troubleshoot your problem logically and methodically.

- If you take something apart, stay organized. Take plenty of photos, mark larger items, and store small parts in labeled zipper-style bags for easy reference.

- Don't be afraid to tackle a repair, or ask for help when needed.

- Electrical problems typically boil down to something that's loose, wet, or has a dirty connection.

- If something fails after completion of a repair or maintenance procedure, that's the first place to start troubleshooting.

3. Bleeding A Diesel Fuel System

Changing a fuel filter often introduces air into your fuel system. This air will typically have to be removed or "bled" from the system to prevent the air from blocking the flow of fuel to the engine. Air removal involves sequentially bleeding the fuel system at specific points.

Have a diesel engine? You’ll need to know how to bleed it after you change the fuel filter. (Photo: Mark Corke)

Your owner's manual will outline the procedure for your particular engine, but here are the general steps:

1. Locate the engine lift pump and manual lever.

2. Loosen the bleed screw on top of the secondary filter (the smaller filter normally attached to the engine) while operating the pump. You only need to loosen the screw slightly, not remove it. Place a container beneath the filter beforehand to catch any spilled fuel.

3. Continue pumping until all bubbles are gone and only clear fuel weeps from the hole , then tighten the screw before you stop pumping.

4. Repeat the pumping procedure, only this time loosen the bleed screw (or fuel line fitting if no bleed screw is present) at the injector pump half a turn, then tighten as soon as clear fuel is ejected.

5. Locate the closest injector to the injector pump — the one with the shortest fuel line. Loosen the injector fuel fitting slightly and continue pumping until clear, bubble-free diesel runs out, then tighten. Repeat this process for each of the remaining injectors.

6. Try cranking the engine. If it fails to start after 10 seconds or so, go back and make sure everything is tightened properly.

4. Unclogging The Head

With the possible exception of, "Where's all this water coming from?" no statement strikes fear into a boat owner's heart quite like, "The toilet doesn't seem to be working." This is particularly true when you consider the issue typically doesn't make itself known until after "the deed" has been done.

The inability to pump the bowl clear is one of the most common marine toilet problems, and it almost always involves a clog or blockage. Somebody flushed something the system couldn't tolerate (no one ever fesses up, by the way) and here we are — an unpleasant situation with an even more unpleasant prospective solution.

For our purposes, we'll assume the toilet is a manual raw-water flush unit, the system most commonly found aboard small to midsized boats.

Why does the head always wait until you're away from the dock to clog? (Photo: Frank Lanier)

Many sanitation systems will have a "Y" selector valve (above), which allows you to discharge bowl contents directly overboard or into a holding tank. Check to make sure the Y-valve is fully open — perhaps even work it a few cycles to verify proper operation.

If you're discharging overboard, at sea in an area where it is legal to do so, verify that the overboard discharge seacock is also open. If you are in a legal overboard discharge area and pumping into your holding tank when the problem occurs, you can also shift your Y valve, open up the overboard discharge seacock, and see if the system works. If so, you've just verified that everything from the toilet to the overboard thru-hull is operational and that the problem lies between the Y-valve and holding tank.

If you're discharging into a holding tank — a more likely scenario — and still unable to empty the bowl, make sure the holding tank is not full and that the holding tank vent hose isn't blocked. Insects like to build nests in the hose if the screen for the hull vent fitting is missing. I've also seen vent hoses clogged with bits of toilet paper or waste.

If the above items check out, yet the toilet handle is difficult to press down and you cannot empty the bowl, chances are you have a blockage in the discharge hose. Start by trying to blast the clog free using a household plunger. Just keep in mind it will only work in one direction, (i.e., the down stroke), due to the one-way valve or flapper (also known as a joker valve) installed at the toilet discharge to prevent waste from backflowing into the bowl. (Confirm with your manual that this method is OK.)

If the plunger method fails, it's time to gird your loins and get dirty. Rubber gloves, old clothes or coveralls, a stout length of wire (a fish tape or untwisted coat hanger) and a 5-gallon bucket are recommended weapons.

Start by disconnecting the hose at the toilet discharge outlet and running the wire down the hose. If you're lucky, you'll find the clog and break it free. Otherwise, it'll be trench warfare from here as you disconnect each successive hose section until the blockage is located and removed.

5. Changing An Engine Raw Water Pump Impeller

The best way to avoid the repercussions of impeller failure (overheating or the need to disassemble the engine cooling system to retrieve impeller pieces) is routine inspection and impeller replacement before failure. Many boaters simply replace the impeller during their annual inspection. It's cheap insurance, and you can keep those in good condition as emergency spares.

Replacing an impeller is a fairly straightforward job. (Photo: Frank Lanier)

While you'll want to follow the instructions provided in your engine owners manual, here are the basic steps for replacing an impeller:

1. Close the engine raw water seacock.

2. Place a shallow pan or spread an old towel beneath the pump to catch wayward parts.

3. Remove the screws that hold the pump's cover plate.

4. Carefully remove the cover plate to expose the impeller. If the cover is stuck, gently pry it free, being careful not to bend or damage it. If the cover is distorted, scored, or has other issues, replace it pronto.

5. Remove the sealing O-ring or paper gasket , depending on the pump make and model. O-rings or gaskets in good shape can be reused in a pinch, but replacement is the best policy.

6. If the impeller has a rubber plug in the center, pry it out with a small screwdriver to see how the impeller is attached to the shaft. Most just slide on, although some may use a thru-bolt or set screw, which will have to be released prior to removing the impeller.

7. To remove the impeller, grasp two impeller vanes on opposite sides (using your thumb and forefinger) and pull/wiggle it out. If that doesn't work, try working it out using two flathead screwdrivers placed on opposite sides, being extremely careful not to damage the flat face of the pump housing. An impeller removal tool constructed of plastic (to avoid scratching the pump housing while prying the impeller out) is a good investment. Another option is using Channel-lock pliers to grip the impeller hub and wiggle it free.

8. Grease the vanes of the new impeller and the wall of the pump chamber. Most impeller kits will include a small tube of lube, but petroleum jelly also works. However, if this would damage your impeller (check manufacturer recommendations), glycerin may be better.

9. Slide the impeller onto the shaft. Folding the vanes while inserting it with a slight twisting motion may make this easier. Installing the vanes in the proper direction is best, however they'll arrange themselves regardless with the first revolution of the impeller.

10. Push the impeller firmly into place , then (if present) tighten the set screw or reinstall the thru-bolt or hub plug.

11. Install the gasket or O-ring as per the impeller kit instructions , and screw the cover back into place.

12. Open the seacock, then start the engine. Check the exhaust for proper water flow. If no water is ejected within a few seconds, shut down the engine and investigate the problem. Check the pump and verify no leaks are present.

Tech Support

It's always helpful to keep technical support phone numbers handy for all of your onboard systems. Many boat owners or captains have them stored in their cellphones for instant use. Before making the call, make sure you can describe the symptoms of the problem and what troubleshooting steps you've already taken. Keep all equipment or system information on hand (e.g., model, serial number) before making the call. Tip: You can store all this information in your phone using Notepad, Notes, or other app. Some apps will even let you add photos of the parts.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Frank Lanier

Contributing Editor, BoatUS Magazine

Capt. Frank Lanier is a SAMS-accredited marine surveyor with over 40 years of experience in the marine and diving industries. He’s an author, public speaker, and multiple award-winning journalist whose articles on boat maintenance, repair, and seamanship appear regularly in numerous marine publications worldwide. Contact him via his YouTube channel “Everything Boats with Capt. Frank Lanier” or at captfklanier.com.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

- Sales: (954) 833-0125

- Service: (954) 466-0121

ONEWATER YACHT GROUP BLOG

Yacht maintenance overview: how to properly care for your yacht.

- June 7, 2021

YACHT MAINTENANCE SCHEDULE

Additional yacht maintenance tips.

YACHT MAINTENANCE RESOURCES & ADDITIONAL INFORMATION

- MTU Diesel Engines have an extraordinary history extending as far back as 1900. MTU is now a subsidiary of Rolls Royce Power Systems. The MTU Series 4000 Diesel has accumulated over 180,000,000 hours of operation. Their engines are developed for a world of large commercial and passenger ships.

- Caterpillar Marine Power Systems . Caterpillar Marine has the most comprehensive range of engine types in the world. CAT engines fall into several divisions including Cruisers, Fishing and Pleasure Craft. Worldwide dealer support is a powerful asset when considering engine types.

- MAN Yacht Engines . The story of MAN Engines can be charted back to 1758 when St. Antony Ironworks began operation in Oberhausen Germany. Owners of a MAN Yacht Engine must sign off on approval of their merchandise, and that is just the introduction of their superb protection.

- Cummins Marine . Worldwide support is a necessary factor when choosing your power plant. Cummins Marine is another recognizable brand that has been building marine engines since 1919. The Cummins Service Network is one of the widest in the world and extremely robust.

- Volvo Penta Marine Leisure . Volvo Penta has carved out a vast swath of the marine propulsion industry. While other engine builders cater to the superyacht niche, Volvo Penta delivers marine systems for yachts in the 60 to 120-foot range. The company has built up a strong group of stern-drive engines for powerboats and a series of engines for sailboats.

- Mercury Marine . Mercury is a well-known brand, and the Mercruiser line of engines are favorites on boats in the 40-foot range or less. Mercury carries a worldwide dealer network. This is a significant advantage when deciding on power. The company offers an extensive line of sterndrive and inboards. The Mercury Diesel is making inroads into larger boats and yachts.

Fuel & Lubrication

Exhaust and air intake, cylinder heads and blocks, electrical systems, transmissions, yacht maintenance costs, one world yacht group service & maintenance, share this article, related articles, discover more at onewater yacht group..

2024 World Yacht Trophies Awards Campaign

The spectacular Ocean 156 wins ‘Best Innovation’ in the 80′ to 98′ category! The Ocean 156, an 80-foot luxury yacht, represents a culmination of Sunseeker’s

145’ Benetti 2022 Sold by OneWater Yacht Group [LUCKY WAVE]

LUCKY WAVE, a 145’ Benetti motor yacht built in 2022, was sold by OneWater Yacht Group. Yacht broker Jeff Schrier from OneWater Yacht Group Tampa

Historic Harbors: Navigating America’s Rich Maritime History with Sunseeker

The United States’ maritime history is best experienced not through books but by visiting the ports and harbors where it was shaped. Exploring these iconic

- Chris-Craft

- Our Inventory

- Global Yacht Search

- Find A Broker

- Service Request

- Sell My Yacht

- Ft. Lauderdale, FL

- Palm Beach, FL

- Annapolis, MD

- New York, NY

- Tampa Bay, FL

- Wilmington, NC

- Dania Beach, FL

DISCLAIMER We strive to ensure all pricing and information contained in this website is accurate. Despite our efforts, occasionally errors resulting from typos, inaccurate detail information or technical mistakes may occur. We are not responsible for any such errors and reserve the right to correct them at any time.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service Apply.

We improve our products and advertising by using Microsoft Clarity to see how you use our website. By using our site, you agree that we and Microsoft can collect and use this data. Our privacy statement has more details.

- Privacy Policy

- Terms Of Use

- Cookie Policy

- Accessibility Statement

- Acceptable Use Policy

- Do Not Sell My Info

Copyright © 2024 OneWater Yacht Group. All Rights Reserved. Powered by Revver Digital

Yacht Maintenance And Repair Services

Our team at Coastal Marine is dedicated to not only getting you back on the water but providing you with first-class customer service, repairs, and maintenance for your vessel. Our team consists of highly skilled technicians and craftsmen who are experienced in every aspect of yacht maintenance, repair, and restoration services. You’re in good hands when you’re aboard our shipyard as our team will go to any length to ensure the ultimate care for your vessel.

- Diesel & Gas Service, Repair & Repowers

- Inboard & Outboard

- Propeller, Rudders, Strut Shaft, And Alignments

- Hydraulic Cranes And Davits

- Vibration Analysis

- Running Gear Repairs

- Metal Fabrication & Welding

- Troubleshooting

- Bow & Stern Thrusters

- Generator Repairs & New Refits

- A/C & D/C Systems

- Battery Replacement

Electronics

- Installation

- Repair & Service On All Marine Electronic Brands

Plumbing, AC & Refrigeration

- Pumps, Hoses & Water Tanks

- AC/Refrigeration/Heads/Water Heaters/ Water Makers

- Thru-Hull Replacement

- Sanitary Plumbing & Holding Tanks

Haul & Launch

- Surveys & Short Haul

- Haul & Prep For Transport

- Launch Of Transported Yachts

- Haul For Service

Damage Repair

- Bottom Encounter Repair

- Hull, Rudder, Keel Repair

- Props, Struts, & Shafts

- Storm Damage

- Insurance Repairs & Claims

Bottom Jobs

- Bottom Painting

- Blister Repairs

- Hull & Topside Painting

- Custom Graphic Design & Application

Fiberglass

- Hull, Deck And Transom Repair

- Custom Fiberglass Installations

Cleaning & Waxing

- Interior Cleaning, Exterior Detailing & Waxing

- Hull & Topside Waxing

- Wood, Aluminum, And Fiberglass

Sales & Service Dealers For

- Mercury Marine

- Interstate Batteries

- PowerPole Anchors

- Magic Tilt Trailers

- Blue Water Desolations

Get In Touch With Us

We’re passionate about boating and helping boaters take care of their investment! Send us a message with your boat’s specific need or call us at 727-576-9315.

Yacht service: getting your sailing yacht ready for the season

A guide to luxury yacht servicing with Oyster Yachts

From water maker and sail checks to winch and engine servicing, this is our guide to yacht service and maintenance that will ensure your readiness for a great season on the water.

Maintain your yacht maintenance log

When taking delivery of their yacht, every Oyster owner receives a maintenance manual and logbook that allows them to easily track their yacht’s maintenance history. The Oyster logbook contains a weekly, monthly, bi-annual, annual, five-year and ten-year servicing checklist which ensures the timely care of the yacht.

Following these time prompts is key to maintaining a healthy and safe sailing yacht, and an updated logbook may also increase the residual value of the yacht if you decide to sell her in the future, as new buyers prioritise well-maintained boats.

We keep records of each yacht’s original plans and build logs, meaning owners can refer to the original specifications and build intentions when commissioning service and refit work.

What to expect from your service

No one understands Oysters better than we do, and our Global Service Network provide annual, seasonal and select service options based on your needs.

Annual services comprise in and out the water essential services unique to your yacht, depending on its current condition and plans for the season ahead. The team undertake work including a 100-point manufacturer check and report, safety equipment service and certifying, structure, thru hull fitting and deck fixing checks and more.

Hauling out allows for the application of new antifouling paint and servicing of the rudder, propeller, seacocks and thrusters, as well as being a good time to polish the hull and superstructure.

When visiting the Global Service Network, our service team will create a list of requirements, scoping everything from canvas work to winches, meaning you can set sail for the season confident in the knowledge you are ready to take on anything.

What to expect from your pre-season check and annual yacht haul-out

Annual pre-season checks and preparations for an Oyster may include:

- Sails valeted

- A visual check of your rigging or official survey of your yacht rig, if in commercial use

- Engines and generators serviced

- All systems checked over – e.g. air-conditioning, refrigeration, LPG, electrics, and electronics

- Annual safety equipment checks

When she’s lifted out of the water for an annual haul-out:

- Antifouling and polishing

- Check of the propeller, shaft and cutlass bearings

- Steering system checks

- Replacement of anodes

- Service of seacocks and thrusters

Where can my sailing yacht be serviced?

Oyster Service Centres are situated in the most popular sailing destinations. In the Mediterranean, Oyster Palma and Oyster Barcelona offer a range of yacht services, repairs and maintenance work.

In the US, Oyster Yachts Newport offers service work from general health checks to emergency repairs and more. In the UK, the Oyster Service Centres in Southampton and Ipswich both offer a broad range of services from refits to annual maintenance and storage.

Everything on your logbook checklist can be carried out by our dedicated teams around the world via our Service Partners in the Global Service Network. Where necessary, we can come directly to you to carry out the required yacht maintenance work.

The Oyster Difference

We understand our yachts and the build process inside out, and our Service work combines in-depth knowledge of each boat, access to trained Oyster technicians, manufacturer’s parts, warranty validation and an up-to-date maintenance log. These factors together have a profound impact on your yacht’s residual value if you decide to sell her in the future.

If you’re not part of the Oyster family, our Service centres are here for you too. Our team of experts are extremely knowledgeable and highly respectful of every kind of boat and have worked on some of the world’s best yacht brands. No matter what you sail, we will endeavour to service your yacht to the highest standards.

Every owner we work with values our trusted team, quality workmanship and unsurpassed reputation to ensure their yacht maintenance is up to date and completed.

To book your Service work, talk to the team here .

Global Service Network

No one understands oysters better than we do. whether you are planning for the voyage ahead, removing uncertainty or ensuring the value of your oyster, it has never been easier with a choice of tailored oyster service plans and our global service network., annual service.

- In and out of the water essential services

- Annual engine services

- Check of structure, thru hull fittings and deck fixings

- Safety equipment serviced and certified

- 100-point manufacturer check and report

Seasonal service

- Pre-cruising season preparation

- Sea trial to test systems

- Decommissioning at the end of the season

Select service

- Extended warranty on equipment and systems

- Service of engine, major equipment and systems

- Check of structure, rigging, thru hull fittings, deck fixings and safety equipment

More information

Find out more

Real-life adventure, sailing insights and everything Oyster Yachts.

Sign up to our newsletter

Be the first to hear about new launches, exclusive events and all things Oyster

© 2024 OYSTER YACHTS

OYSTER WORLD RALLY

Entries for the Oyster World Rally 2028-29 are now open. Embark on the sailing adventure of a lifetime

The new 565 Series II

The pursuit of perfection continues

Oyster Charter

Experience exhilarating sailing, luxury and style on an Oyster charter

New 565 Series II

LUXURY CHARTER

Experience exhilarating sailing, luxury and style on an oyster charter. personal, exclusive and uniquely oyster.

Oyster 825 iSNL

Discover this exceptional late model 825 with a unbeatable spec and a bespoke layout.

oyster ownership

Personalised care, unforgettable experiences and lifelong yacht support, oyster world rally.

ENTRIES OPEN

Embark on the sailing adventure of a lifetime. entries are now open for the oyster world rally 2028-29.

Follow the Oyster World Rally 2024-25 fleet live

Winner of European Yacht of the Year 2023. She is a new breed of luxury 50 foot yacht, offering effortless shorthanded sailing capability.

A magnificent, award-winning sub 60 foot sailing yacht, offering luxurious living space and outstanding shorthanded sailing capability.

A beautifully proportioned 60 foot, luxury liveaboard bluewater cruiser, offering effortless shorthanded sailing capability.

A superb sub 70 foot ocean sailboat offering versatile luxury living space and impeccable sailing performance.

An inspired 75 foot yacht, offering infinite configuration options, generous luxury living space and flexible crew quarters.

Oyster 885SII

The remarkable, iconic 90 foot sailboat, perfect for relaxed luxury voyages of discovery.

First name *

Last name *

Phone number *

Country/Region *

Attach CV *

Attach covering letter

Current occupation

LinkedIn profile

Boat Repair: Choosing a Marine Mechanic

A good boat or personal watercraft technician can help you enjoy your boat by keeping it running reliably and by competently installing accessories that can make your time on the water more fun. Finding a good mechanic can be challenging, however. Luckily we're here to provide you with some tips and answer some of the most commonly asked questions about boat repair.

What Does a Boat Mechanic Do?

You hire a marine technician to maintain your boat and its engine , to prepare it for off-season storage , or to repair any system that is not functioning correctly. As an alternative to performing your own maintenance, the service of a quality technician will help keep your boat reliable and your time on the water trouble-free. In most cases, a good tech has skills and tools you probably don’t have.

Why Do I Need a Boat Mechanic?

Even if your boat never needs a repair, it will require periodic maintenance . There are some maintenance items most boat owners can learn to handle themselves, such as checking engine oil level or removing the propeller to check the propshaft for tangled fishing line. But today’s marine engines and electronics are complex, and proper service often requires special training and tools. Unless you have the time and desire to acquire those skills and tools, the services of a good marine technician are a smart investment.

At the very least your boat engine will require annual maintenance to keep its warranty up to date. And many boat owners will need to have the vessel prepared for winter storage at the end of the season.

How Can I Find a Good Marine Technician?

If you are buying a new boat from a marine dealer, ask about the service department before you close the deal:

- Ask to meet the service manager.

- Get a quick tour of the service shop area. That shop should look clean and well-organized.

- Ask how long the service manager has been in the business.

- Ask about the level of training the dealership’s technicians have completed.

Marine engine manufacturers have extensive training programs that lead to the certification of “master technicians” who have passed very challenging tests. If the shop has master technicians, there may be certificates, like diplomas, hanging on the walls. It’s also fair to ask about the typical wait time for service at the dealership, which can be weeks during peak season if the shop is short-staffed. Many dealerships will try to make sure their new-boat customers have a priority position for service during the season.

A larger boat with more systems, such as navigation or fishing electronics, a generator, galley plumbing or air conditioning, may require a technician with specialized skills. In some markets a dealership will rely on a contractor to handle some of this service, but it’s good to ask ahead of time.

In addition to training certification from marine engine and electronics manufacturers, inquire about technical certification through the American Boat and Yacht Council (ABYC), which eight specialty certification classes. An ABYC Master Marine Technician has passed at least three of those classes.

You may also need service for other aspects of boating, such as:

- A boat lift technician or service to remove the lift for the winter.

- A good general auto repair shop can also help maintain boat trailer wheel bearings and tires.

You can check the internet for feedback on a marine facility, but word of mouth remains a solid endorsement. Before choosing a facility, ask for referrals from fellow boaters or someone you trust in the marine business. Keep in mind that while their rates may be higher, a facility that invests in good diagnostic equipment and in certified technicians typically offer better service.

How Much Will a Boat Mechanic Cost Me?

Labor fees for marine technician service can vary by region and season, but the basic charge will be similar to the rate charged for labor at an automobile dealership, between $70 and $120 per hour. Rates may be lower in the winter or off-season when the shop is not very busy, and some facilities will have a fixed charge for a standard annual engine service or for winterization. More specialized service can cost more; the service of a factory-certified marine diesel engine technician may cost more than $175 per hour.